What size motor best suits a fan? It is a common question that is more complex than one would imagine. Many variables exist based on an application. Different technologies also affect the fan selection. The following will discuss torque, horsepower and fan laws.

Here is an example.

“My direct drive fan has a brake horsepower of 0.40 hp. Why does this fan have a ¾ hp motor?”

This is a great question. No one wants to pay more for a motor that is larger than needed for the application. However, the real question is really about motor sizing and getting the proper performance from the unit.

Moving air is a variable Torque process

First, let’s define torque. Torque is the twisting force that causes rotation. All fan wheels or propellers spin, so a fan requires torque.

To answer the example question, it is important to understand that fans are a variable torque application. This means when a fan starts, it is spinning very slowly and moving very little air (CFM). The amount of force (torque) required to turn the impeller also is very low because there is very little resistance to overcome (static pressure). As the fan’s RPM increases, it takes an increasingly larger amount of torque to spin the impeller. The reason that the torque requirements go up with RPM, is that as the fan spins faster and it moves more air (CFM). This increased airflow caused by the fan spinning faster also increases resistance that the fan must overcome.

Torque and Horsepower are related

Torque creates a twisting action on the impeller shaft. Horsepower (HP) is the amount of work done over a specified period. In fans, HP is the application of torque over a given time. An equation that describes the torque and HP relationship exists.

HP = (Torque x RPM)/5252.

What does this mean? Basically, if RPM, torque or both increase, the HP it takes to run the fan will also increase. Therefore, the more air you want to move, a greater amount of HP is required.

The Fan Laws

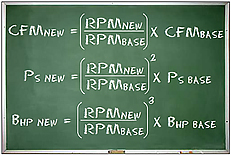

Several terms previously mentioned have an effect on airflow. The terms RPM, CFM, static pressure, and HP actually have a relationship. This relationship is most commonly called the fan laws or affinity laws. Three basic fan laws address these terms.

The first fan law shows that the change in RPM is directly proportional to the change in RPM. (Figure 1) An example of this is if there is a 10% increase in RPM, the result is a 10% increase in CFM.

|

| Figure 1 – Fan Law |

The second fan law indicates that as RPM increases, static pressure (Ps) also increases. But this change is not proportionate. The Ps will actually increase by the square of RPM change. Since the change in RPM is the same as CFM change, this shows that as more air is moved, the resistance to flow increases greatly.

The third fan law connects how HP is affected by the change in airflow. This law states that the amount of HP required to move air in a system, is multiplied by the cube of the change in RPM.

If the RPM increases by 10%, the CFM will also increase by 10%. This same change will increase the Ps to 21% and the HP required to overcome the Ps and move the air will increase by 33%.

Torque and HP have a proportional relationship. The fan laws agree with information mentioned previously that more air moved requires more torque!

Air movement is a variable torque process and key terms in air movement are all related. A future post will put this information into practice and show how a motor is sized in fan applications.

Fans Motors

from