Understand the Energy Efficiency Codes Before Selecting an Inline Fan

A Brief History Behind Fan Efficiency

It all started in 1975 when increasing energy use and high energy prices prompted Congress to pass legislation for improving energy efficiency. Congress required the states to set energy efficiency requirements instead of establishing a national code. Each state was responsible for addressing energy and efficiency.

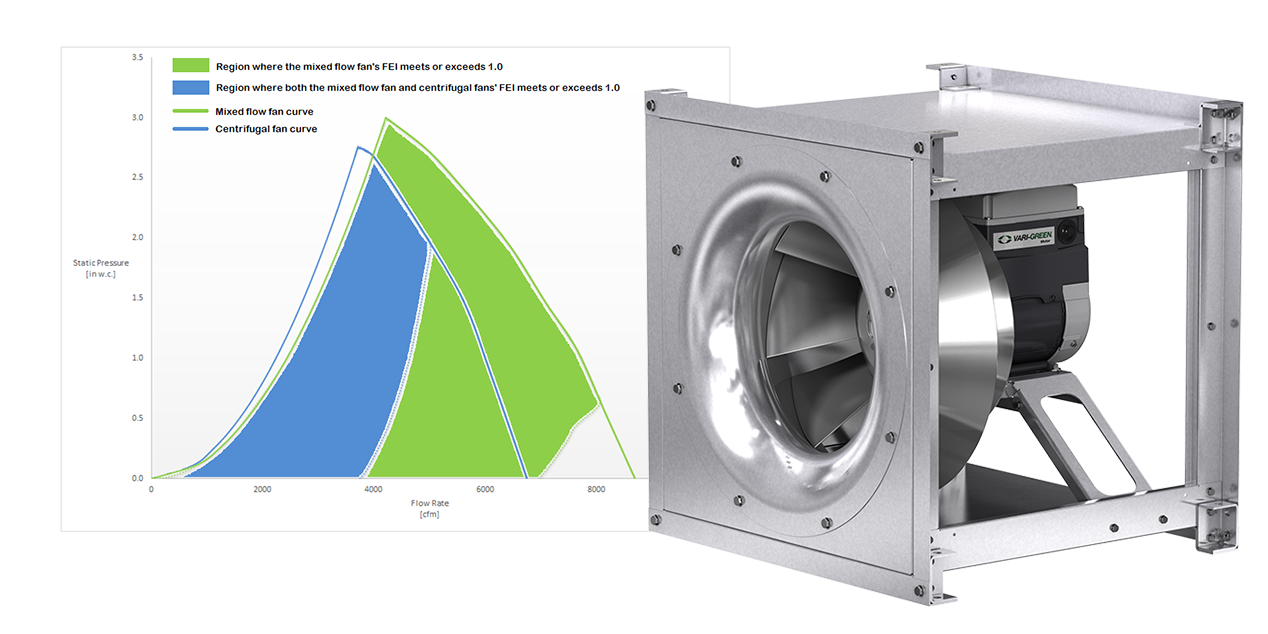

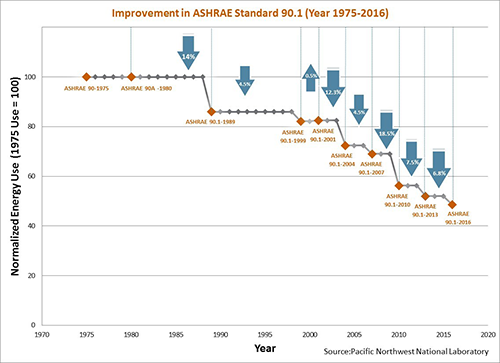

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) developed an energy standard for commercial buildings in 1975. ANSI/ASHRAE 90.1 Energy Standard for Buildings except Low-Rise Residential Buildings provides direction for HVAC engineers and designers to design building projects that meet or exceed the minimum energy requirements. ASHRAE 90.1 is not a static standard and continues to drive energy reduction (Figure 1) in the commercial building industry. Heating, ventilating, and air conditioning (HVAC) equipment consumes large amounts of energy. Even with improvements, an average of 40% of a commercial building’s energy use is from HVAC equipment. |

| Figure 1 |

Fan Efficiency Grade

ASHRAE setting the 90.1 energy standard was a first step. Also needed was a simple means of calculating and testing efficiency. The Air Movement and Control Association (AMCA) developed AMCA Standard 205, Energy Efficiency Ratings for Fans which included the introduction of fan efficiency grades (FEG), and the FEG metric was, in 2013 version of the 90.1 standard. Also in 2013, the United States Department of Energy mandated that state energy codes meet or exceed the current edition of ASHRAE’s 90.1 standard within 3 years of its publication. That meant that the FEG included in ASHRAE 90.1-2013 be adopted by states by 2016.

FEG measured a fan’s aerodynamic ability to convert mechanical power to air power. This measurement was a step forward in setting standards and providing a basis for comparison for fan performance. However, FEG was not an accurate assessment of a fan’s real power consumption. FEG had limitations that:

- Were based on a single point of peak efficiency, not the fan’s operating range

- Did not include energy losses with the motor and drive

- Had significant exceptions related to static and total pressure applications

Fan Energy Index

In 2011, the U.S. Department of Energy (DOE) began to develop regulation pertaining to commercial and industrial fans. With the assistance of manufacturers and industry organizations, fan efficiency index (FEI) emerged as the preferred metric due to its ease of use in selecting the most efficient fan. The DOE’s effort halted in 2017. Still, various parties have adopted FEI to continue drive down fan energy consumption.

FEI is a superior measure of fan efficiency because it incorporates the losses inherent in every portion of a fan system, including the motor, drives and/or speed control, transmission (bearings, belts, and pulleys), and aerodynamics; FEG does not. FEI is a simple ratio of a reference fan’s electrical input power versus an actual fan electrical input power, with 1.0 being the minimum threshold. This simple ratio allows FEI to be used as a direct comparison of two fans’ energy consumption, regardless of the fan type. The result? When you specify a fan operation point, selecting the highest FEI value ensures getting a fan with the lowest energy consumption. With FEI’s inclusion in the 2019 version of ANSI/ASHRAE 90.1 and the International Energy Conservation Code (IECC), became the key metric for lowering energy costs, meeting code, future regulatory targets, and capturing energy reduction incentives or rebates.

We’ve covered, briefly, a history of fan efficiency and why FEI provides the best way to compare fan efficiency. Let’s turn the discussion back to inline fans and use FEI to help us weigh our selection options. Inline fans serve as an excellent example of FEI in practice when used in many applications, such as offices, education, and health care.

Figure 2 compares two inline fans of equal size where one fan uses a traditional centrifugal wheel while the other fan uses a high-efficiency mixed flow wheel. If you compare the area where the FEI value is greater than 1, it is apparent that the mixed flow wheel option provides a much larger selection area, particularly as the flow rate increases. What does this mean? It means that not only is the mixed flow option more efficient, but the mixed flow wheel gives you both the ability to downsize your fan or to target higher FEI values to capture potential incentive or rebate opportunities!

|

| Figure 2 -- Comparing Fan FEI Performance Envelop |

HVAC equipment manufacturers are making great strides to improve energy efficiency while complying with the codes and standards. Learn more about the extremely efficient inline mixed flow fans.

from