Considerations for Warehouse Summer Ventilation Systems

Heat builds up in warehouses and distribution centers in the summer months without proper ventilation. Summer ventilation systems exhaust heated air from the warehouse and replaces it with fresh outdoor air. These systems replace the air in the building 1 – 3 times per hour, which minimizes the difference in temperature inside and outside and provides air movement through the facility. Warmer climates will utilize a higher airflow rate and cooler climates will utilize a lower airflow rate.

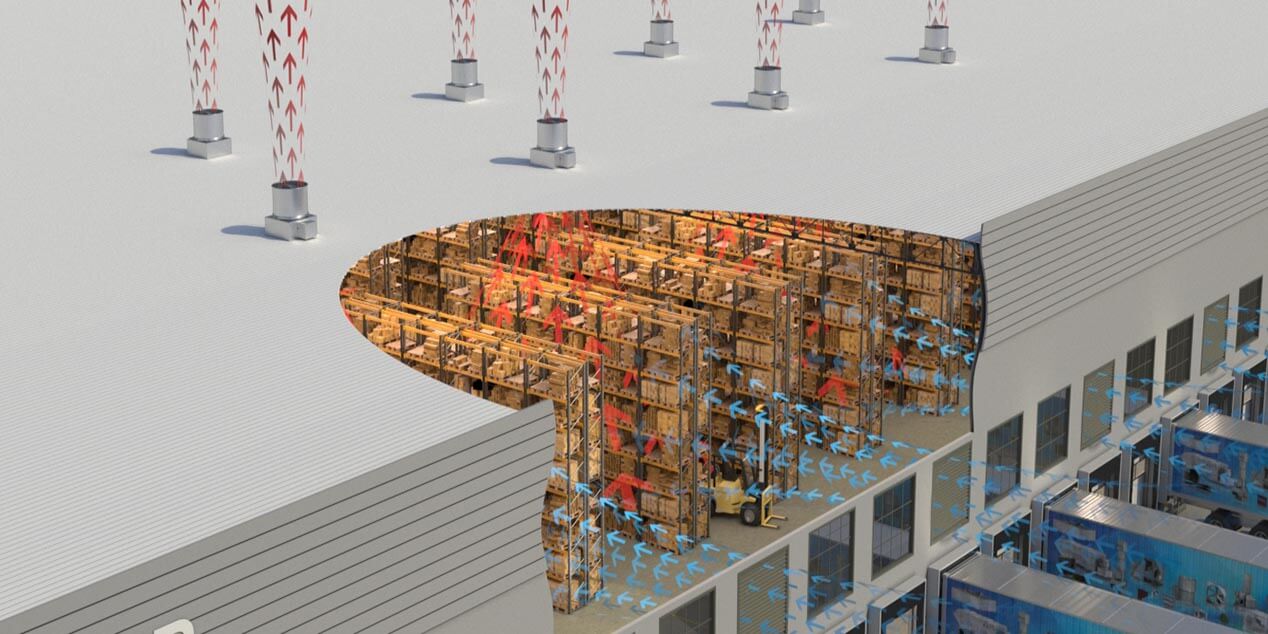

Summer ventilation systems can be implemented in a variety of different configurations. Some common configurations include (Figure 1):

- Roof exhaust and intake louvers

- Sidewall cross ventilation

- Sidewall exhaust and roof intake

- Roof exhaust and roof intake

|

| Figure 1 |

Of these design strategies, roof exhaust and intake louvers is the most common because it is highly cost effective and most efficient.

Many options exist when selecting the right intake louver for warehouse summer ventilation systems. Intake louvers protect intake openings against rain infiltration. In cool climates, a heating system takes over in the winter and the summer ventilation system is disabled. Closing the intake openings prevents cold air from entering the space during the winter. This requires using dampers in conjunction with the louvers or an operable louver that functions as a conventional louver in the open position and provides shutoff in the closed position.

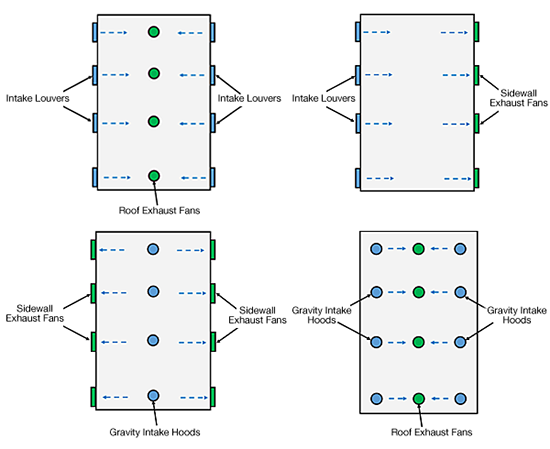

Adjustable Blade Louvers

Adjustable blade louvers (Figure 2) are designed such that the entire louver blade operates. In the open position, the blades are positioned at an angle and function as a conventional louver. In the closed position, the entire blade operates creating shutoff. These louvers are the most cost-effective intake option for warehouse summer ventilation systems. However, the entire blade rotates and does not maintain the architecturally desirable fixed louver appearance in the closed position. Additionally, adjustable blade louvers tend to have higher leakage rates in the closed position than other options.

|

| Figure 2 -- Adjustable Blade Louver (Model EAD-635) |

Combination Louver/Dampers

Combination louver/dampers (Figure 3) feature fixed front louver blades with operable damper blades. These operable louvers maintain the architecturally desirable fixed louver appearance in both the open and closed positions and may have slightly lower leakage than adjustable blade louvers. Combination louver/dampers generally cost slightly more when compared to adjustable blade louvers.

|

| Figure 3 -- Combination Louver / Damper (Model EACA-601) |

Stationary Louvers and Dampers

Conventional stationary louvers (Figure 4) combined with a damper are generally the highest cost option for warehouse summer ventilation but provide more flexibility for the application. Dampers have lower leakage ratings than operable louvers minimizing the amount of unwanted air leakage into the facility.

Additionally, insulated damper options help reduce heat loss through the air intake opening and prevent condensation or frost buildup inside the damper are available.

|

| Figure 4 -- Stationary Louver (Model ESD-635) and Insulated Thermally Broken Damper (Model ICD-45) |

Many options exist when selecting roof exhaust fans. Common fan options include axial upblast, hooded axial exhaust fans and spun aluminum centrifugal exhaust fans.

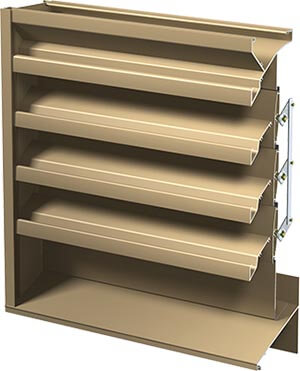

Axial Upblast Fans

Axial upblast fans (Figure 5) are the most cost-effective solution for summer ventilation in large warehouses. These fans also are the most efficient for the large airflow capacities of 30,000 – 60,000 cfm, commonly seen in warehouse summer ventilation systems. No field assembly simplifies installation. Integral butterfly dampers prevent unwanted air from entering the building when the system is disabled in the winter. A disadvantage of axial upblast fans, however, is serviceability because some components are difficult to access from the roof.

|

| Figure 5 -- Axial Upblast Exhaust Fans (Model RBUMO) |

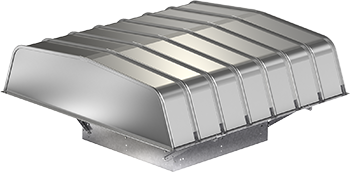

Hooded Axial Exhaust Fans

Hooded axial exhaust fans (Figure 6) have similar performance to axial upblast fans but tend to be more expensive, and large sizes require the hoods to be field assembled. Additionally, installing a separate backdraft damper prevents unconditioned air from entering the building when the system is disabled in the winter. One key advantage the hooded design provides is additional protection against wind and rain. Hooded axial exhaust fans are also generally easier to service because belts, pulleys, motors, and bearings can all be accessed from the roof.

|

| Figure 6 -- Hooded Axial Exhaust Fan (Model RBE) |

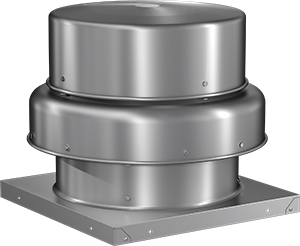

Spun Aluminum Centrifugal Exhaust Fans

Spun aluminum centrifugal exhaust fans (Figure 7) also are used in warehouse summer ventilation systems. These fans have lower airflow capacity and the centrifugal wheel is not as efficient in low pressure, high airflow operating conditions required for warehouse summer ventilation systems. Key advantages for spun aluminum centrifugal exhaust fans are that the fans provide similar protection against wind and rain as hooded exhaust fans and do not require any field assembly making for easy installation. Additionally, they provide easy access to belts, pulleys, motors, and bearings, simplifying service.

|

| Figure 7 -- Spun Aluminum Centrifugal Exhaust Fan (Model GB) |

Summer ventilation systems are one part of a complete warehouse HVAC system. Learn more about a total HVAC solution for warehouses and distribution centers.

Fans Louvers Warehouse Ventilation

Read Next

Louver Requirements for the Hurricane-Prone Region

Addressing Two Trends that will Strain Efficiency in the Warehouse

Benefits of Heating Warehouses with Direct Gas-Fired Equipment

from