Topic:

Fans

How to Survive a Retrofit Fan Installation in a Tight Space Location

|

December 29, 2020

Specifying and installing a [physically] large fan and its related housing in new construction frequently is quite easy. Exposed openings allow contractors to move it to the required location. However, that same installation to replace the existing equipment becomes far more difficult years after the building’s completion. Obstacles such as finished entrances, hallways, stairways, or doorways no longer allow free movement to the old fan and installation of the replacement.

Your Options from Radical to Easy

Several options exist to offset the challenge of fan installations with space restrictions. You could remove all the obstacles that prevent easy access. However, it is unlikely the building owner would approve the added construction cost, noise and delays it would cause.Another option is using a fan that is physically smaller than the access limitations. Depending on the age of the model being replaced, it is possible that a newer compact version is available that still meets your performance requirements.

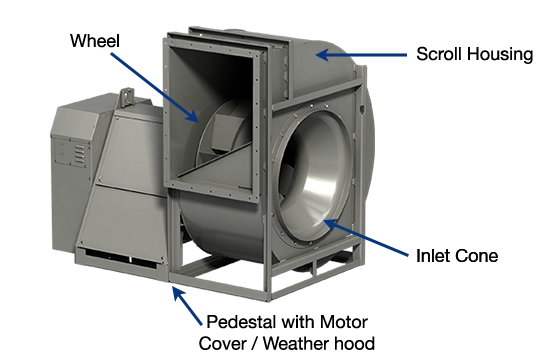

Fan units with bolted construction components are another option. These components have dimensions verified by the manufacturer, making it easy to know whether the size of the individual components allows for installation when access is limited. Major components of bolted construction are the scroll housing, inlet cone, wheel, and pedestal. (Figure 1)

|

| Figure 1 |

Still, situations exist where a smaller size fan or bolted construction components will not work and a [physically] larger fan are required. Quite often, the fan’s scroll section is the largest part of the fan assembly and too large to maneuver through door or stairways. This is where a third option—split housing units—works very well.

Split Housing Units

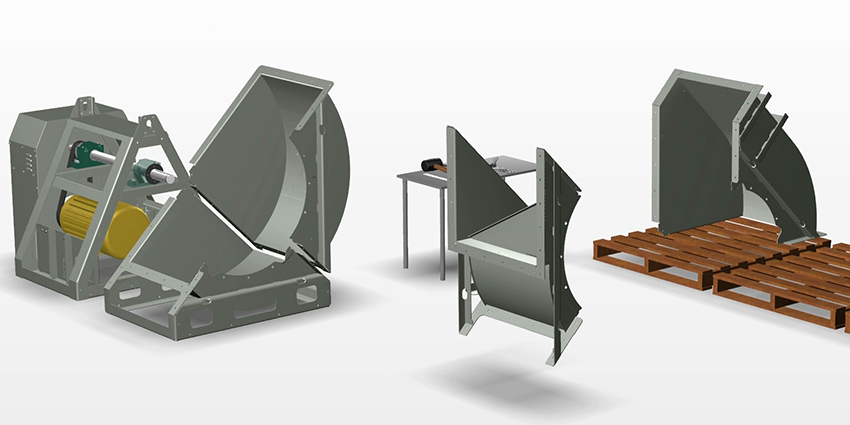

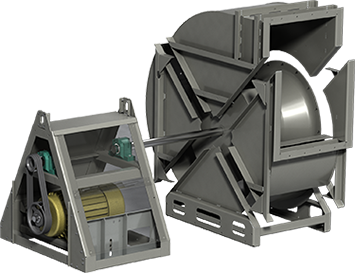

Split housing units have a design that allows for the disassembly (and reassembly) in the field—exactly for this type of situation. The scroll is constructed with a split, called a split housing. (Figure 2) Subsections of the scroll are factory cut with welded flanges for a bolt-together assembly. The additional flanged joints allow the unit to be broken down further into even smaller sections. This allows you to move the smaller parts into position through the restriction, and then reassemble it once it is past those access restrictions.

The following video shows the steps required to disassemble and reassemble a fan in the field for situations such as the one we described. (Note the model used is now a USF-500)

|

| Figure 2 |

Retrofit installations can cause problems, particularly when space limitations exist. Options are available. Learn more about the split housing fan option.

Fans

Other Blog Topics

Other Blog Topics

from