The proper selection of louvers can be complex as many variables determine how they will perform. An understanding of basic louver performance criteria including free area, air volume, the beginning point of water penetration, and pressure drop can help guide your louver selection process. These performance criteria should be included in a manufacturer’s louver performance submittals. While none of these criteria offers enough information for louver selection alone, when combined, they will provide direction for selecting the best louver for the application. The following breaks down each of these criteria.

Free Area

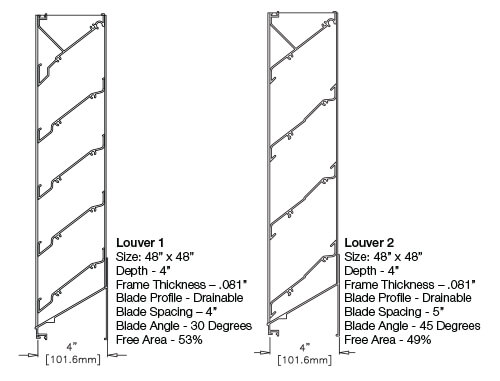

The free area of a louver is defined as the total louver face area, minus the airflow restrictions (blades and frame) through which air can freely pass within the openings. Louver frame depth, component profiles, louver blade spacing, and louver blade angle all play a role in determining the louver free area. Free area is a major determinant of a louver’s performance capabilities. The goal is to allow as much air as possible to pass through the louver while keeping out unwanted water or debris. Too great of a free area and the louver cannot reject water. Too little free area and the louver becomes an unwanted restriction to airflow. Free area is often represented in square feet or as a percentage of the total louver face area. You should pay close attention to manufacturers’ performance submittals as even similar models within the same performance category can have noticeably different free areas (Example 1).

|

| Example 1: Free Area |

Air Volume (CFM)

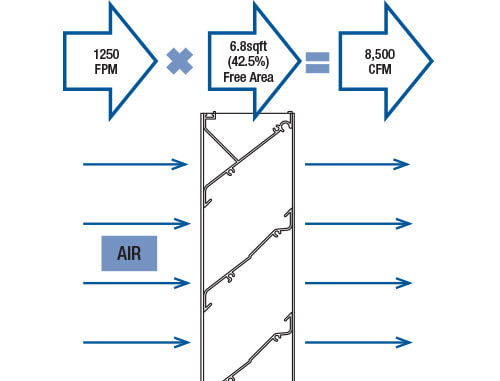

Air volume flow rate is the measurement of air flowing into or out of a space measured in cubic feet per minute (CFM). Louvers allow air to pass through the building envelope and into the HVAC system while keeping water and debris out of the intake airstream. Additionally, louvers must provide the required system CFM per square foot of louver free area to the air handling equipment to ensure operation at peak performance. Louver CFM is calculated easily by multiplying the proposed air velocity (FPM) by the free area (sq. ft.) of the louver (Example 2).

|

| Example 2: Air Volume |

The Beginning Point of Water Penetration

The beginning point of water penetration is the moment at which .01 oz. of water will pass through a louver at a given intake velocity measured in feet per minute. The ability to prevent water penetration through a louver is an important criterion for louver selection. As previously discussed, louver design allows air into buildings while keeping out unwanted water and debris. A complex arrangement of specific louver blade profiles, the angles of the blades, blade position, spacing, or a combination of blade position and spacing all contribute to the degree of minimizing water penetration.

Pressure Drop

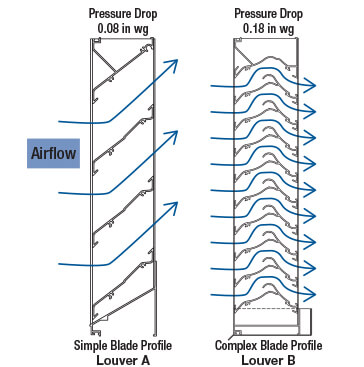

Pressure drop is the resistance to airflow across a louver stated in inches of water. The level of airflow resistance is a significant factor in louver selection. Factors affecting pressure drop are the same for the beginning point of water penetration. A negligible pressure drop allows a high degree of airflow but may also allow water and debris through the louver opening. Conversely, a high-pressure drop may not allow an acceptable airflow. The latter may place a strain on air-handling equipment, causing it to work harder, resulting in increased energy cost and greater acoustic noise or the need to invest in more expensive air-handling equipment. With louver products, the pressure drop is a measure of airflow resistance typically displayed as inches of water gauge at specific free area velocities. Free area and the aerodynamic properties of the louver product are among the items that play a part in determining pressure drop. Most louvers have a pressure drop in a range between 0.03 - 0.50 in. wg (Example 3). Lower pressure drop is generally considered more advantageous. Note that high free area is not necessarily synonymous with low-pressure drop.

|

| Example 3: Pressure Drop |

Factoring in a louver’s free area, air volume, the beginning point of water penetration, and pressure drop can help you specify the best performing and aesthetically pleasing louver to meet the demands of a high-performance HVAC system.

In our next Louver Fundamentals blog post, we’ll break down the various Air Movement and Control Association (AMCA) International test standards that ensure louvers perform as specified.

Louvers

Read Next

from