Fire Dampers 102: Application, Installation, Options, and Accessories

In our Fire Dampers 101 blog post, we discussed the different types of fire damper products and the associated testing and rating requirements. In this post, we will examine the correct application and installation of fire dampers, and review some of the available options and accessories.

Application

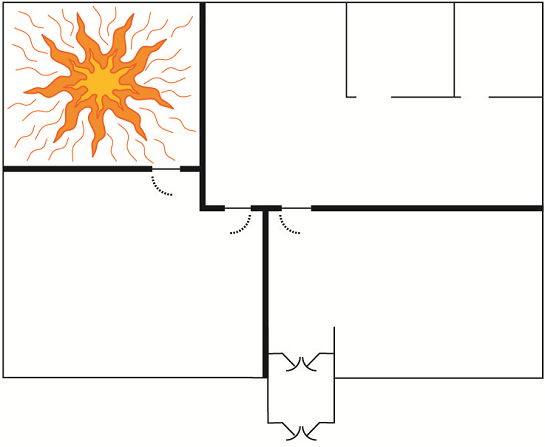

One of the basic requirements of building fire protection is the compartmentation, or dividing up, of buildings using fire-rated walls and floors. This compartmentation concept is intended to contain any fire to the compartment of origin and thereby minimize property damage and protect the lives of people living and/or working in the building. A duct or ventilation opening in any of the fire-rated partitions could permit a fire to spread from the compartment of origin to adjoining compartments. Fire dampers are installed in these duct or ventilation openings. They close automatically upon detection of heat by a heat-responsive device (usually by the melting of a fusible link), blocking the opening and preventing the spread of fire into the adjoining compartment.

|

| Fire rated partitions contain fire damage to the compartment of fire origin |

Installation

The IBC (International Building Code) requires life safety dampers to be installed “in accordance with the manufacturer’s installation instructions and the damper’s listing.”

Mounting Orientation

Fire dampers are required to pass separate tests for vertical mount and horizontal mount applications. Dampers need to be installed in the correct orientation to ensure life safety and proper fire protection. Every fire damper is supplied with a label indicating the required mounting orientation. Mounting orientations are not interchangeable unless the damper is specifically labeled for use in both horizontal and vertical orientations.

Vertical mount fire dampers must be installed in masonry, block, or stud walls. Horizontal mount dampers must be installed in concrete floors, except when using the I503 horizontal non-concrete construction design (For more information, refer to IOM: UL Design I503 or VIDEO: UL Design I503).

|

| Horizontal Fire Smoke Damper in Non-Concrete Barrier |

Preparing the wall openings

Wall openings must be framed out in accordance with the damper manufacturer’s installation instructions. All construction and fasteners must meet the requirements of the appropriate wall design (see UL Fire Resistance Directory) and /or local codes. Openings should be “square,” meaning the two diagonal dimensions of the opening should be equal… even for true round dampers!

Clearances required between damper sleeves and wall or floor openings

Fire damper assemblies expand during periods of intense heat. Therefore, it is essential that openings in walls or floors are larger than the fire or combination fire smoke damper assembly to allow for this expansion. This “gap” is commonly referred to as the expansion clearance or annular space and should never be filled with any foreign materials or sealants unless specifically allowed per the manufacturers’ installation instructions. See installation instructions for the minimum required clearances.

Sleeve Requirements

All UL fire and combination fire smoke damper listings require that the damper be mounted in a steel sleeve of a specified gauge and length before installation. A factory-supplied sleeve ensures the correct gauge is used, and the damper will be ready to install. If the sleeve is installed in the field, the installation instructions show how to attach the sleeve and damper. The sleeved damper assembly is installed in the wall or floor opening and retained as part of the structure by angles attached to the sleeve. UL requires that any connecting ducts terminate at each end of the damper sleeve.

Sleeve gauge requirements depend on the damper size and type of duct-to-sleeve connection used. See the manufacturer’s installation instructions for the minimum requirements.

Installing damper/sleeve assembly in wall and floor openings

Fire dampers must be installed so the centerline of the frame is mounted within the wall or floor opening, except for dampers designed to specifically mount outside the plane of the wall/floor opening. Retaining angles are used to secure the damper assembly into the opening. See the manufacturer’s installation instructions for two-sided and single-sided angle installation methods. Additional installation methods may be available (i.e., 3-Sided Retaining Angle Installation VIDEO or Single 3-Sided Retaining Angle IOM) depending on the manufacturer and model.

|

| Installation of Fire Smoke Damper Within Wall Opening |

Duct-to-Sleeve Connections

When dampers require a duct-to-sleeve connection, UL allows a rigid or breakaway connection. A rigid connection is, by UL’s definition, any connection that has not been qualified as a breakaway connection. All qualified breakaway connections must be described in the damper manufacturer’s fire and combination fire smoke damper installation instructions.

Options and Accessories

Closed Indicator Switch – a high-sensitivity hinge lever used on curtain fire dampers that sends a signal when the damper blades close.

|

| Closed Indicator Switch |

Open or Closed Indicator (OCI) – a switch assembly used on multiblade fire dampers to provide positive open and closed damper blade position signals.

|

| Open or Closed Indicator (OCI) |

Transitions – different options are available to match the damper size/shape to the duct size/shape and reduce pressure drop. Options are available to keep curtain-style blade stacks and damper frames out of the airstream and maximize free area when the damper is in the open position.

Breakaway connections – UL approved duct-to-sleeve attachment options.

Security bars – round steel bars welded into the damper sleeve can be used to reduce security risks and reinforce the equipment.

Clean wrap – a thin film that adheres to the ends of the damper sleeve to prevent dust, dirt, and debris from entering the damper at the construction site.

Retaining angles/retaining plates – single or two-sided angles can be ordered with the damper, pre-cut to the correct dimensions with holes at 1” increments to facilitate ease of installation. Retaining plates are included with true round fire dampers to allow installation into a square opening.

|

| Retaining Angles |

For more information about Greenheck fire dampers, click here.

Dampers

from