The impact HVAC grilles and registers have in a total ventilation system may seem small compared to the system overall. However, a fraction of an inch in the spacing of the grille or register blades makes a big difference. Most supply and return grilles use 3/4" blade spacing, but evidence suggests switching to a 2/3” offers a better result on several levels.

Aesthetics

Most building owners are concerned about increasing costs to operate a high-performing ventilation system. However, aesthetics plays a role in product selection, particularly in offices and other high-profile settings that require a pleasing symmetrical appearance.

Grilles and registers having a 3/4" blade spacing will have asymmetrical gaps between the blades and frame. This spacing means registers and grilles will look as if the manufacturer could have made a mistake in the product construction because of its asymmetry.

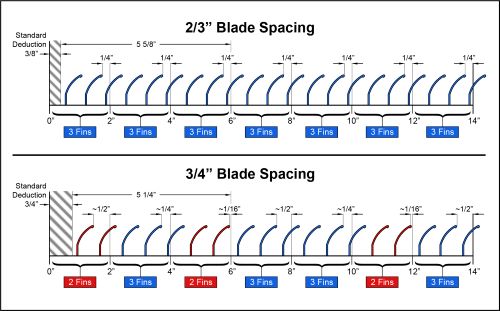

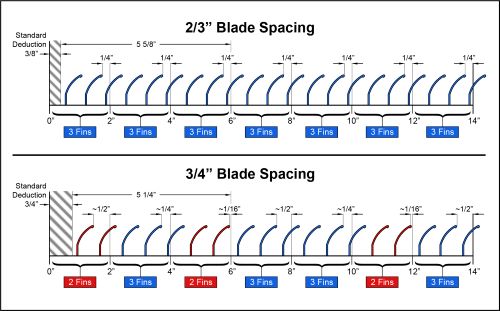

However, grilles and registers constructed using a 2/3” blade spacing offer perfect symmetry and a more pleasing look to the overall interior design. A 2/3” blade spacing ensures the grille or register will have three blades for every two-inch increment. A grille or register having a 3/4" blade spacing will not. A 3/4" blade spacing may have two blades in the same two-inch space one time and three in another. The grille also will have an oddly spaced gap, creating an asymmetry issue. (Figure 1)

Another important benefit of using grilles with 2/3” blade spacing is that there are more blades installed for any given size. Having more blades allows for more finely tuned control of the airflow pattern and deflection angle and allows engineers to more accurately direct the air where it needs to go.

|

| Figure 1: Diagram showing Greenheck products (top) with reduced standard deduction and 2/3" blade spacing compared to products with 3/4" blade spacing (bottom) |

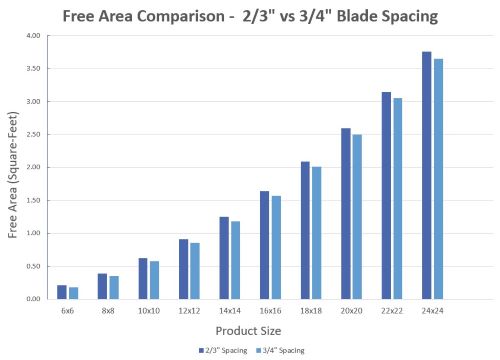

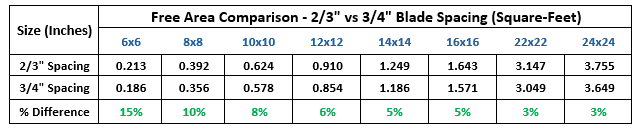

Free Area

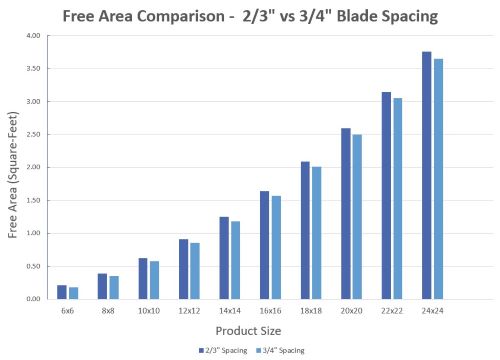

The free area of a grille or register can affect the effectiveness of a ventilation system by offering lower static pressure and sound levels. The role of blade spacing in the free area is quite significant. One might expect a 3/4" blade spacing would provide more free area than a 2/3” spacing. However, this expectation is not correct. The 2/3” spacing offered by Greenheck provides 1% - 15% more free area than comparable grilles and registers with 3/4" blade spacing. This difference is due to the standard deduction. The standard deduction is the difference between the product size and the actual opening.

Another way to describe it is the clearance between the wall substrate and the product. Most manufacturers in the industry use a standard deduction of 3/4". However, Greenheck uses a reduced standard deduction of only 1/2" to 3/8” for most grilles and registers. This standard deduction allows for a slightly larger face area than the competition for any given size. The combination of the larger face size and the 2/3” blade spacing yields a larger overall free area than products that use 3/4” or 1/2" blade spacing.

Every Greenheck return grille and most supply grilles offer the engineer and building owner more free area than a comparable product having 3/4" spacing. A few exceptions exist, but only on supply grilles larger than 18” x 18”. Very few projects specify those grilles. Below is the data to compare the free areas between products with 2/3” and 3/4" blade spacing. (Figure 2)

|

| Figure 2 |

National Fire Protection Association (NFPA) and Blade Spacing

The NFPA 90A-2021 standard 4.3.7.3.2 and 4.3.8.3.2 requires the ability of grilles/registers to prevent a debris sphere of 1/2" from penetrating the product and entering the HVAC system. This standard is applicable to all return grilles that are located less than 7 feet above the floor. All grilles/registers having blades spaced at 3/4" cannot comply with this standard without using additional accessories. It requires grilles and registers to use 1/2" or 2/3” spacing to meet the code as detailed in the standard. It is still possible to use products with 3/4" spacing, however, they must be paired with an accessory such as an insect screen to comply with the standard. A change like this can add high cost and cause coordination issues on a project if some spaces in a building can use grilles with 3/4" spacing and others must use 1/2" spacing to comply with fire codes. However, an effective and cost-efficient alternative is using grilles with 2/3” spacing throughout the space because these grilles/registers comply with fire codes where required and provide greater free area.

Ensuring an efficient ventilation system requires attention to small details, such as blade spacing. Specifying engineers should strongly consider grilles and registers with 2/3” spacing because it offers better free area and aesthetics over the spacing 1/2" or 3/4" currently used. The 2/3” spacing also meets the NFPA 90A-2021 standard, eliminating the need to change from 3/4" spacing in one area and 1/2" spacing to meet fire codes. Grilles and registers having 2/3” blade spacing allow for uniform grilles throughout the space. You can learn more about grilles and register blade spacing by contacting your local Greenheck representative or checking out grilles, registers, and diffusers on our website.

Grilles, Registers & Diffusers

Mike Collins

Mike Collins

Mike Collins is a Segment Engineering Manager for grilles, registers, and diffusers (GRD) at Greenheck. Mike holds a bachelor’s and master’s degree in mechanical engineering from Florida State University with an emphasis on heat transfer and fluid dynamics.

from