EC Motor Fundamentals: Choosing the Right Motor—EC versus Belt Drive

New developments in EC motor technology and a growing list of benefits make EC motors attractive options in fan applications. But do these benefits make traditional belt drives obsolete? Let’s consider why customers select EC motors.

All motors in fan equipment have two magnetic fields located in the rotor and stator. The traditional induction motor requires both fields to be generated. However, an EC motor has a permanent magnet rotor, which only requires the generation of the stator magnetic field, making it more efficient. An EC motor also incorporates an integral drive into its design. This drive can monitor the load on the motor to adjust power consumption. The end result is a vastly more efficient product in partial load conditions.

Advantages and Disadvantages

Since no power source is perfect, one expects the traditional and EC motors to have advantages and disadvantages. The following are the advantages of using a conventional belt drive set-up:

- Speed adjustments—Adjustable pulleys or an external variable frequency drive (VFD) allow for relatively easy and precise speed adjustments (balancing) on belt drive fans.

- Available for use on most fan sizes.

Unfortunately, traditional belt drive fans have many more disadvantages:

- Power transmission losses

- More noise and vibration

- Maintenance requirements on belts and bearings, as well as replacement of these items

- Additional weight

The EC motor offers many advantages:

- Allows for direct drive fans to be used instead of belt drive to the motor's speed adjustability

- A minimal amount of maintenance

- Less noise and vibration because of fewer moving parts

- Lighter weight

Many EC motors can have one disadvantage. Controlling fan speed may require purchasing an additional device. EC motors need a speed reference to know how fast to go. The most common methods are either a potentiometer or a 0-10V modulating signal. The speed reference can come from many sources, such as a remote dial, a stand-alone controller, or even a Building Management System (BMS). Greenheck’s Vari-Green® motors eliminate the confusion by allowing you to select a dial and/or 0-10V wiring harness to be provided with the fan.

Another perceived disadvantage of EC motors is the limited range of motor sizes. The current range of sizes for EC motors is from 1/15 hp up to 10 hp, leaving large fans to use traditional belt drive motors. Fortunately, research on EC motors continues to produce new and larger-sized motor options.

Energy Consumption

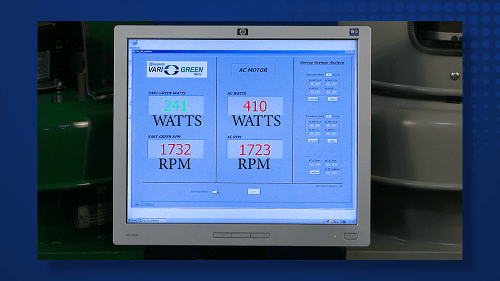

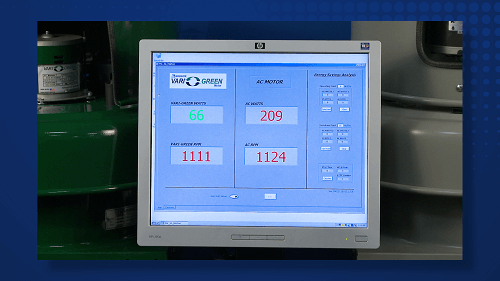

A direct drive fan with an EC motor is more efficient than an AC motor and belt drive version. But saying so does not make it correct. However, comparing the two fans will demonstrate the difference in energy consumption and efficiency.

|

| Image 1 |

|

| Image 2 |

Controls

Fan systems in this modern world often require other add-on features such as reacting to the environment to meet set conditions. Control options such as constant pressure or constant airflow, maintaining indoor air quality keying off of volatile organic compounds (VOCs), temperature and humidity, and others are necessary to maintain a safe and productive environment.

Cost

Comparing the EC and belt drive fans is not as simple as it sounds. Belt drive fans appear to cost less than the typical EC motor-driven fan. Still, EC motors, such as Greenheck’s Vari-Green® motor, are not as expensive as one might think. The difference in cost could be plus or minus 10%, depending on fan type and size.

A belt drive fan often requires a motor starter or VFD in many applications. These additions increase the cost. Reliability is another cost consideration since the belt drive will need more maintenance to repair and replace moving parts, including belts, pulleys, sheaves, etc. As EC motors have fewer moving parts, the operating cost is less—often 30% to 50%. Therefore, the perceived savings between the initial cost of a belt drive fan are nonexistent when factoring in add-ons and operating costs.

Conclusion

Conventional belt drive fans do offer benefits in some application settings. However, as size capabilities for EC motors have increased, the number of applications where belt drives are the better option have shrunk. The best way to determine the correct design for your application is to investigate Greenheck’s Vari-Green® motors and then contact your local Greenheck representative for the best option.

Motors Vari-Green

from