Addressing the Challenges of Operating Room Air Distribution

What differentiates critical environments from regular commercial construction is the necessity for very carefully controlled parameters for the quality of air. These parameters could include specific temperatures, humidity, pressure, velocity, particle

counts, oxygen content, etc. In addition to these parameters, in critical environments such as operating rooms, there is also an enhanced focus to reduce biohazardous particles such as viruses, bacteria, and mold spores. These can be generated from

different sources such as operating room staff, components brought into the operating room, or even from the patients themselves.

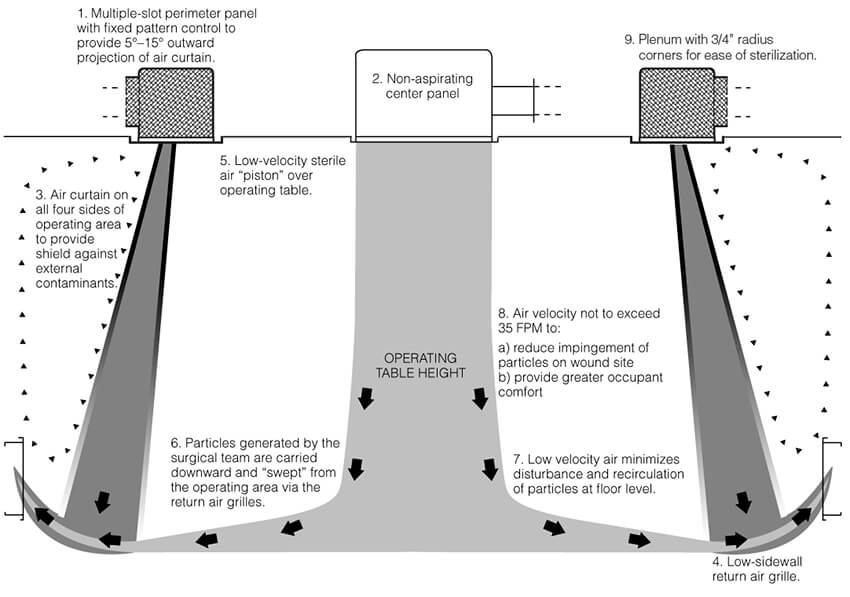

The VA Design Guide for Surgical Services outlines the main goal of an HVAC system in an operating room as follows: “(In an operating room,) the air supply system must be designed to minimize airborne bacteria from entering the sterile field, in addition to keeping the remaining operating room as clean as possible.”1 This goal can be achieved through an air curtain system. (Figure 1)

|

| Figure 1: Air Curtain System |

Air Curtain Systems

Air curtain systems consist of laminar flow diffusers and a perimeter of high-velocity air curtains combined with sidewall returns located near the floor. This combination allows for slow-moving, clean

air to be vertically supplied from the laminar flow diffusers, while the air curtains along the perimeter help to create a barrier against contaminants. In general, an air curtain system can allow for careful control of velocities and particles,

however, an air curtain system such as Greenheck’s HLC-SAC goes a step further and combines accurate airflow balancing with ease of installation.

With the HLC-SAC system as shown in Figure 2, the air curtains help to maintain low-velocity laminar flow over the operating table. When air curtains are used in conjunction with laminar flow diffusers, the high-velocity air curtain creates a jet with lower pressure which induces the laminar airflow. The central laminar airflow is pulled outward into the perimeter high-velocity jet, filling the zone within the curtain with low-velocity laminar airflow. This induction and expansion maintain true laminar flow within the operating zone. Since the low sidewall returns are used to extract the airflow, this helps to keep particulates flowing away from the operating room table and out of the space.

Another important function of an air curtain system is to prevent any particles from outside the curtain from re-entering the sterile field. Figure 2 also illustrates the expansion and induction of the laminar flow plume into the high-velocity air curtain jet in the air curtain system.

|

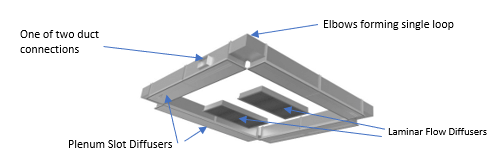

| Figure 2: Greenheck HLC-SAC System Cutaway Overview |

The air curtain effectively creates a barrier against external contaminants from outside the operating area. Since the laminar flow diffusers provide sterile air over the operating room table, it is important to ensure that no contaminants can make it to the operating area. An air curtain perimeter accomplishes this by establishing a boundary by which no particles can infiltrate from outside the table area. The sterile supply air washes over the patient and can carry away particulates or biohazardous materials which are then swept away by the high-velocity jet and extracted by the sidewall return.

The Greenheck HLC-SAC System is unique because the entire perimeter of air curtains consists of a single plenum. This single “loop” plenum allows for only two duct connections for the entire perimeter. This saves the installer much time and effort since many comparable systems use a handful of inlet connections. When a system uses multiple inlets, each inlet will require airflow balancing to maintain equivalent velocities through each air curtain and any change in overall system pressure will require rebalancing. If the air curtains have different velocities, this can cause the entire system to function incorrectly thereby increasing the chance of contamination.

In the HLC-SAC system, once both duct connections are active, the entire loop becomes pressurized. As the plenum loop becomes pressurized, each air curtain along the perimeter will maintain the same velocity. This makes the Greenheck HLC-SAC system one of the easiest operating room systems to install, as well as one of the most effective systems for maintaining a clean operating room.

Click here for more information on Greenheck’s HLC-SAC air curtain system or contact your nearby Greenheck representative.

References

- U.S. Department of Veterans Affairs. 1993. Design Guide: Surgical Service, Draft 11-15-93

from