The National Education Association cites that nearly 57.5 million students and school employees enter the doors of our nation’s schools every day. According to estimates from the U.S. Environmental Protection Agency, half of these adults and children spend their school days breathing air polluted with toxic chemicals, mold, viruses, bacteria, asbestos, pesticides, smog and particulates from vehicle pollution, and more. While the threat of severe illness from viruses such as COVID may have subsided, the need for safe and healthy indoor air has not. In addition to schools, many building spaces remain vulnerable to the negative effects of poor indoor air quality. Since the COVID pandemic, the concept of indoor air quality (IAQ) has expanded to include the concept of indoor air safety (IAS). Given that most people spend 90% of their time indoors, it is more important than ever to address the IAS risks associated with pathogens, wildfire smoke, and VOCs. The most reliable method for reducing threats to IAS is the multilayered utilization of HVAC technology and products.

Products that address ventilation, humidification, and filtration ultimately provide the best opportunity for assuring safe indoor air. Of these options, effective ventilation is the most reliable option for improving and maintaining IAS. In fact, the utilization of effective ventilation is the only technology solution available that mitigates CO2 and concentrations of dangerous pathogens.

An effective ventilation system assures IAS in a building by accomplishing two fundamental functions:

- Replacing contaminated air from the building with fresh air from outside,

- Keeping air circulating throughout the building to prevent pollutants from accumulating in dead zones.

Products that are proven effective in providing these functions include:

- Dedicated outdoor air system (DOAS) equipment

- Energy recovery ventilators

- Air distribution equipment

These and other new products that are effective in maintaining key air safety metrics such as relative humidity, CO2, PM2.5, and VOC levels provide the foundation for assuring IAS. While some codes set requirements for various elements of indoor air quality, related standards are in a state of ongoing development to stay current with ever-changing safety issues. For example, ASHRAE just announced the release of a brand-new standard 241, titled “Control of Infectious Aerosols”. This standard has yet to be ANSI approved or adopted by any codes. In the absence of established standards and code requirements, the following items provide a fundamental starting point for assuring indoor air safety levels for building occupants:

- CO2—Keep CO2 levels under 1000 ppm to reduce concentrations of dangerous pathogens AND improve worker productivity and student test scores;

- Relative humidity—40% to 60% is the best range to mitigate the risk of pathogens AND provide optimal comfort to occupants;

- PM2.5—Use MERV 13 or higher-rated filters to achieve PM2.5 levels at or below 12 μg/m3. If the PM2.5 level goes to or above 35 μg/m3 during a 24-hour period, the air is considered unhealthy and can cause issues for people with existing breathing issues such as asthma. Using MERV 13 or higher filters will also mitigate the entrainment of wildfire smoke and related outdoor air pollutants.

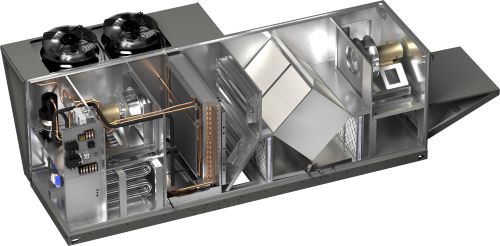

DOAS

Dedicated Outdoor Air Systems or DOAS equipment can provide up to 100% of the outdoor air requirements for effective ventilation. Rooftops are the typical location for the placement of DOAS equipment, but some DOAS units have capabilities for use on the ground next to a building. Some manufacturers offer features that provide fully conditioned outdoor air and the ability to provide precision temperature and humidity control in addition to housing filters capable of reducing particle matter in the air. To help reduce heating and cooling loads associated with effective ventilation levels, some manufacturers incorporate energy-saving enthalpy wheels or cores to transfer energy from the contaminated exhaust air to the fresh supply air.

|

Energy Recovery Equipment

Energy recovery ventilators (ERV) can often be added to existing rooftop units (RTUs) preventing the need to change out and upsize RTUs to meet new air conditioning loads associated with increased ventilation rates necessary to meet IAS requirements. The ERV reduces conditioning loads by transferring heat, cold, and humidity from the stale, contaminated exhaust air to the oxygen-rich incoming outside air. Energy recovery can offer an enthalpy recovery ratio of up to 80% and help meet requirements of standards such as ASHRAE 62.1 and 90.1.

|

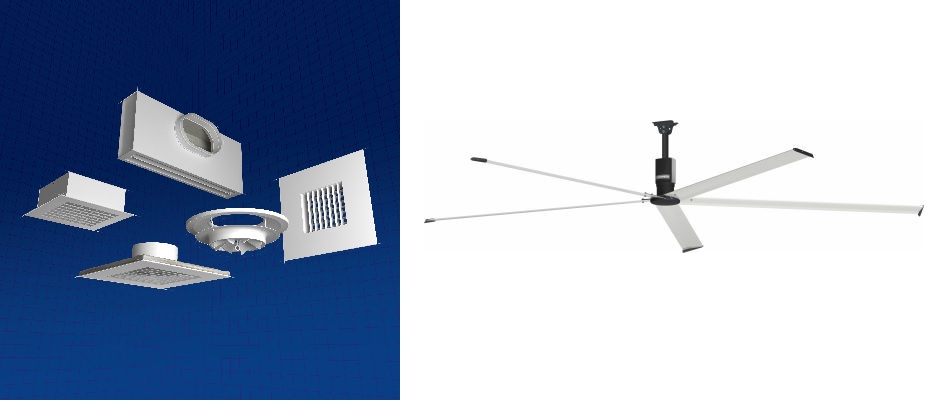

Air Distribution Equipment

Grilles, registers, diffusers (GRDs), and overhead ceiling fans also play a critical role in achieving safe indoor air. These products offer an effective means of distributing air in a space, preventing stagnation and the accumulation of harmful particulates or gases in dead zones of a room.

GRDs help direct air to assure effective ventilation to minimize high concentrations of contaminants. GRDs also ensure rooms maintain a constant temperature by directing airflow toward areas more affected by temperature fluctuation, such as exterior walls and windows.

Overhead fans (sometimes referred to as High Volume Low Speed fans (HVLS) or Large Diameter Ceiling Fans (LDCF)) also assist in airflow distribution and direction to ensure air movement in larger areas. While helping to keep air from becoming stagnant, HVLS fans can also increase occupant comfort and reduce energy costs by reducing temperature and humidity stratification in the room.

|

Addressing Existing Equipment and Products Designed for IAS

Building owners that installed new equipment prior to the COVID pandemic may ask whether their system meets the evolving requirements for indoor air safety. This is a fair question since the investment in HVAC equipment is often significant. While many pre-COVID HVAC systems were beginning to embrace updated IAQ standards, much of the equipment in these systems may only meet minimum levels for IAQ/IAS. Older equipment that fails to meet even minimum indoor air safety requirements may need to be modified or replaced to assure safe levels of indoor air quality.

Updating or replacing outdated equipment in an existing building can be challenging. Before making updates to HVAC systems and/or equipment, designers should always verify the performance of the installed systems and components. Designers may also find it prudent to focus on space-specific IAS solutions such as large gathering areas, classrooms, or offices rather than the entire building's HVAC system. Regardless of the type of equipment installation, it is wise to consult a qualified professional such as your local Greenheck representative to help determine the best course of action to assure indoor air safety for your project.

Available Grants

Improving or replacing ventilation components and systems can be a large financial investment. Fortunately, federal grants are available to help offset the cost if your situation qualifies. Grants for IAS include tax dollars from the American Rescue Plan and CARES Act. These grants are mainly for government buildings, schools, and universities. Businesses can apply for grants for energy code updates through the Inflation Reduction Act. Your local Greenheck representative can help you navigate this information, too. Plan to contact them today!

Indoor Air Quality

from