In today’s world of harmful chemicals, particulate matter, and noxious gases, bubble-tight dampers are more important than ever. A bubble-tight damper is an isolation damper designed to meet the performance requirements for zero leakage in critical leakage applications such as clean rooms, medical facilities, test laboratories, federal buildings, microelectronics manufacturing, and food processing.

When specifying bubble-tight dampers, you want to ensure they are properly built and tested before leaving the factory to be installed on your project. For decades, bubble-tight damper performance has been dictated to comply with the rigorous standards of the nuclear industry. Today, two standards dictate performance testing requirements for bubble-tight dampers:

1. ANSI/AMCA Standard 500-D-12 Paragraph 6.2.2.5.5:

Damper setup for bubble test (Test Figure 5.8) - For bubble tests, one reading per determination of test pressure (Ps9) and damper inlet dry-bulb temperature (td9) shall be recorded. The size of bubble formation shall also be recorded by noting if any bubbles exceed 1.6 mm diameter (1/16 in.) in 1 second or if any bubbles exceed 7 mm (1/4 in.) diameter in 1 minute.

2. ASME AG-1, 2015, section DA 5141:

Seal Leakage Test for Leakage Class 0 Dampers (Bubble Method) - The damper shall be bolted to a pressure chamber that is then pressurized to the specified blade design pressure. A bubble solution (a commercial test solution or a solution consisting of equal parts liquid detergent, glycerin, and water) shall be applied to the damper seat area to be tested. A few moments later, but before the soap solution can dry, check the wetted areas and mark places where bubbles are being generated. Unless otherwise specified, a leak indication is any bubble 1/16 in. (1.58 mm) diameter that forms in 1 second, or a bubble 9/32 in. (7.14 mm) that forms in 1 minute.

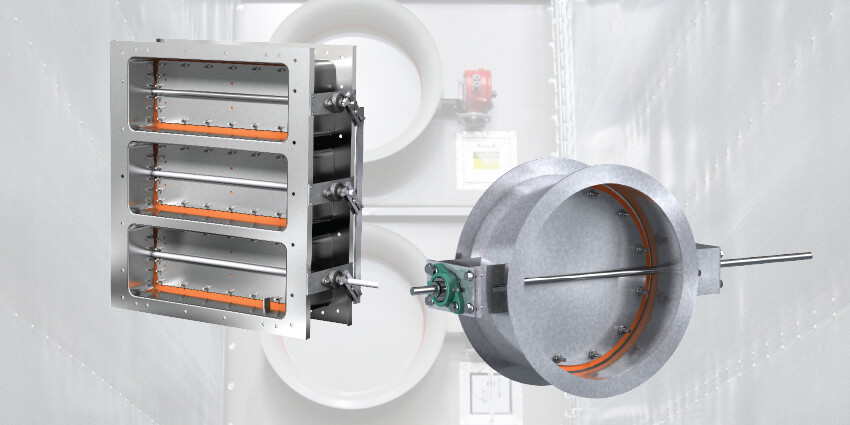

At Greenheck, every bubble-tight damper we manufacture is tested to the AMCA 500D requirements which also meet the ASME AG-1 standard (and the obsoleted ASME N509 test standard) for nuclear air and gas treatment. Greenheck has five bubble-tight models that meet today’s AMCA and ASME requirements.

| Model | Shape | Pressure Rating |

| HBT-221 | Rectangular | 10 in. wg |

| HBT-321* | Rectangular | 20 in. wg |

| HBTR-151 | Round | 10 in. wg |

| HBTR-451 | Round | 30 in. wg |

| HBTR-551 | Round | 40 in. wg |

| *coming soon | ||

Designed to perform under the most demanding requirements, these dampers provide safety and reliability and are tested to meet or exceed these AMCA and ASME requirements before shipping from our factory.

When specifying bubble-tight dampers, reference ANSI/AMCA Standard 500D or ASME AG-1, Section DA bubble-tight requirements to ensure you receive the best isolation damper for your critical application.

Click here for more information on Greenheck HBT and HBTR bubble-tight dampers or contact your nearby Greenheck representative.

Dampers

from