Many different types of floor mounted isolators exist for a variety of applications and fan equipment.

Isolator Types:

Neoprene/Elastomeric Floor Mounted Isolators

Application – Neoprene isolators (Figure 1) are designed to limit the transmission of structure-borne vibration and impacts that can lead to shortened life of the equipment. These isolators lessen the generated audible noise from high frequency vibration caused by high RPM in HVAC equipment.

Installation - Your submittal drawing should determine the position of the neoprene isolator and the isolators can be identified by the color. Neoprene isolators are easy to install and do not require adjustment once placed under the equipment. Indoor or outdoor installation is possible; however, extended UV exposure may cause some degradation.

|

| Figure 1 -- Neoprene Isolator |

Free Standing Spring Isolator (FDS)

Application – Free-standing isolators (Figure 2) are used to isolate floor-mounted equipment located near areas where a quiet environment is critical. FDS isolators reduce the transmission of vibration and sound from low RPM HVAC equipment.

Installation – FDS isolator position should be determined by your submittal drawing and the isolators can be identified by the color-coded springs. Use FDS isolators indoors or outdoors, but do not expose to lateral forces that could result in bent or broken leveling bolts or springs. An FDS isolator is not appropriate for seismic or wind applications.

|

| Figure 2 -- FDS Isolator |

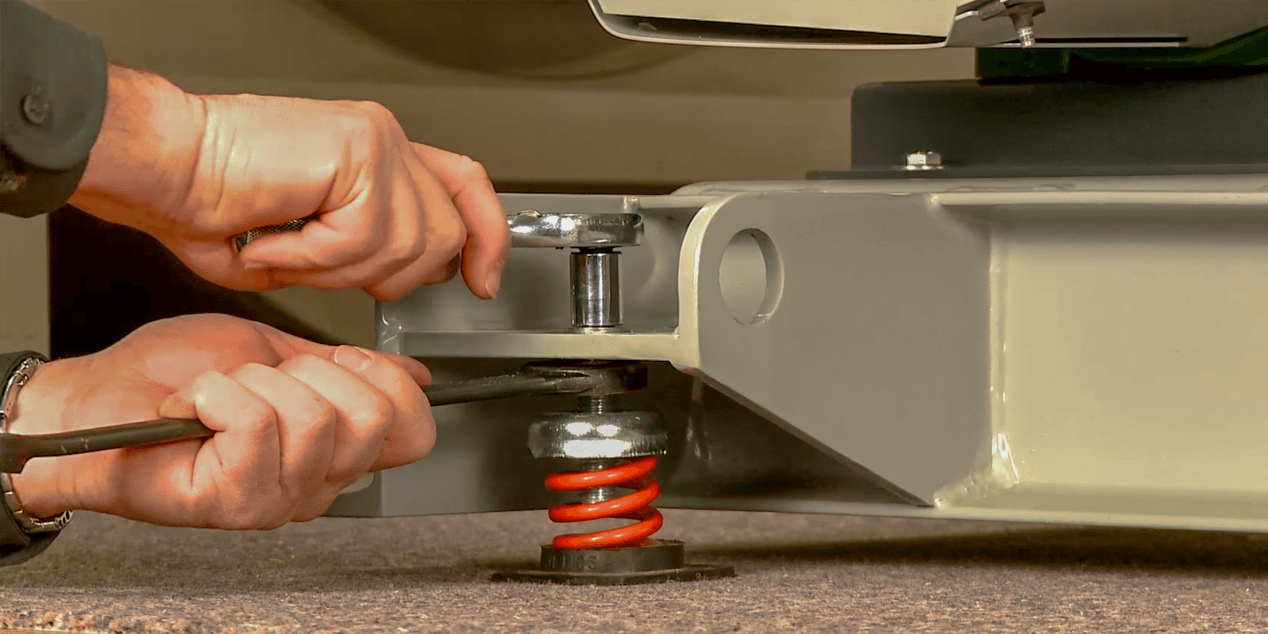

Restrained Spring Isolators (FHS)

Application – Restrained spring isolators (Figure 3) reduce the transmission of noise and vibration into supporting structures from supported mechanical equipment. FHS isolators are recommended for noise and vibration isolation for mechanical equipment located near critically quiet areas when there is a possibility that the equipment being isolated will be subjected to the external forces such as wind or an earthquake.

Installation – Determine FHS isolator position from by your submittal drawing. Isolators can be identified by the color-coded springs. FHS isolators typically are used outdoor where equipment can be exposed to lateral forces such as wind or an earthquake

|

| Figure 3 -- FHS Isolator |

Before you Begin

- Consult your Submittal for proper isolator layout

- Follow proper Lock-out Tag-out procedures to ensure the equipment is not energized and safe to work on

- Inspect the equipment to insure there are no rigid connections to the duct work or electrical utility

- Tools required for the job

- Leveling block

- Pry bar

- Wrench or ratchet and socket for the isolator leveling bolt and cap screw

- Follow the instructions for making the adjustments provided on the video

The video explains in more detail how to successfully install and properly adjust your HVAC equipment isolation.

Selecting the best isolators for your HVAC equipment is the first step to take and eliminate unwanted high and low frequency noise and vibration. Greenheck.com has several resources to answer many of your isolator questions.

from