Many options exist for building ventilation. Most options depend on the building’s use. For example, warehouses, distribution centers, and manufacturing buildings often use a combination of gravity and powered fan equipment to ventilate the facility. This method is popular because it offers effective and low-cost options to replace indoor air with outdoor air. A common design used for effective air changeover in these spaces is a mix of intake gravity hoods or louvers with exhaust rooftop axial fans. You may wonder why this is common, and the answer is simple - the ventilation of these applications attains a low dollar per CFM ($$/CFM).

How to Determine $$/CFM

Here is an example to help explain $$/CFM:

Let’s assume there is a project for a 500,000 sq foot warehouse facility with 30-foot ceilings. Roughly 60% of the facility requires ventilation in summer to maintain comfortable conditions. The specifying engineer calls for four air changes per hour and calculates 0.2 in wg of static pressure. The structure allows for 20 roof penetrations for the equipment. The following equation shows how we arrive at these requirements:

[(500,000 x 30) x 0.6 x 4] / 60 = 600,000 cfm for summer ventilation.

600,000 / 20 fans = 30,000 cfm at 0.2 in wg.

|

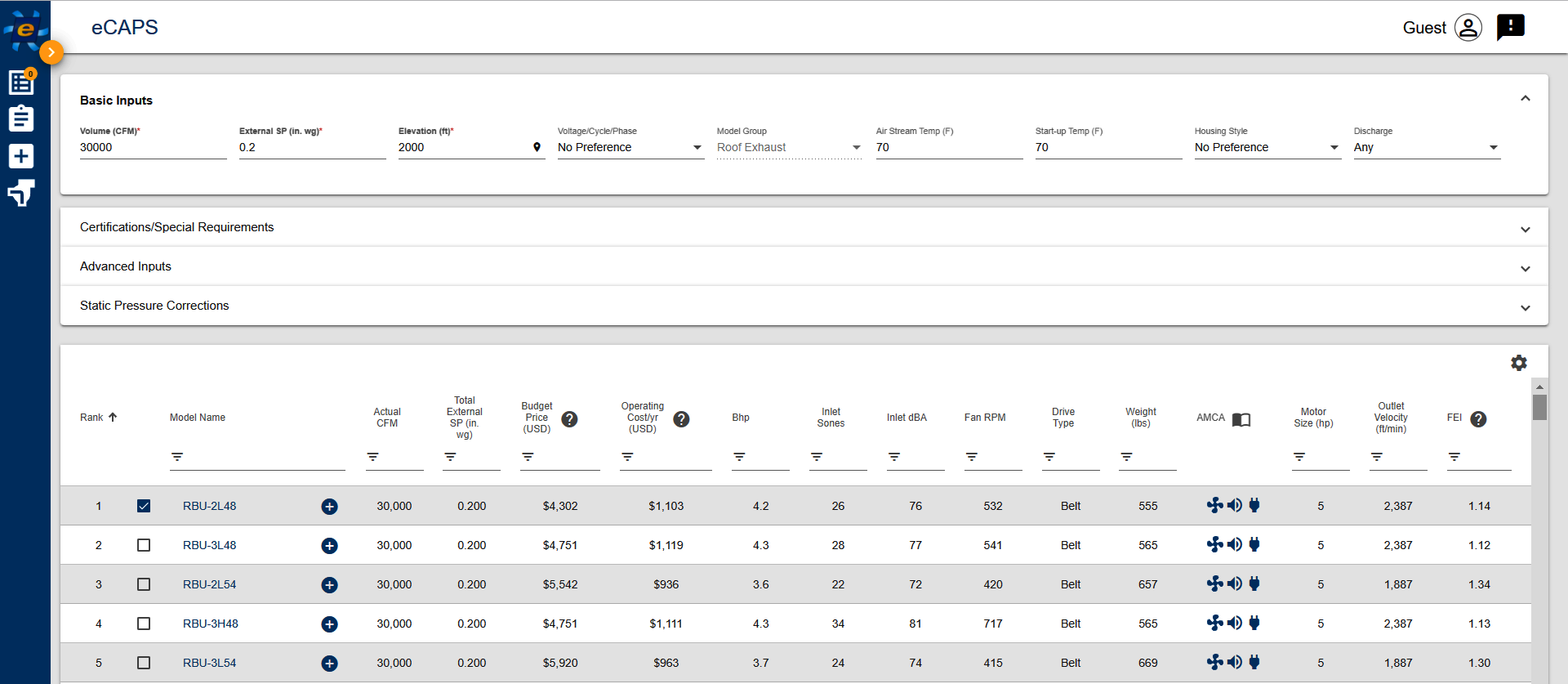

The most cost-effective $$/CFM equipment options are easy to find when using an online product selection program. We will use Greenheck’s eCAPS (https://ecaps.greenheck.com) platform for this example.

|

| Figure 1 |

There, you can see that the best options for powered roof exhaust from a $$/CFM aspect are axial (propeller) roof fans based on the budget price. Furthermore, the best choice for lowest budget price is a propeller upblast fan (model RBU-2L48). (Figure 1) These fans have a low first cost to purchase, arrive on-site fully assembled, and are relatively inexpensive to operate.

|

Consider the Hidden Aspects of $$/CFM

Often, $$/CFM only accounts for first cost and not operating, maintenance or installation costs. Think about these other factors contributing to the overall cost of the equipment and the overall $$/CFM. How does the product ship? Are components factory-installed or do components come shipped loose for field assembly? Some HVAC equipment manufacturers attempt to artificially deflate the $$/CFM by reducing sell price by shipping components such as motors and drives loose or unassembled to the fan, then having field installers assemble the final product on-site. Finishing the assembly in the field adds more time and expense into installation; and drives the overall $$/CFM much higher. Maintenance costs are another consideration. The propeller upblast fan from our selection example (model RBU-2L48) appears the best choice for first-cost and operating costs. However, belt and motor maintenance are done from inside the building. This servicing may require moving racking or equipment in the facility, leading to hidden maintenance costs. The example shows another fan, model RBUMO-2L48. It also is an upblast fan but has the motor out of the airstream. The cost is slightly higher but offers similar performance. The difference is its construction--designed to simplify maintenance by allowing belt and motor access from the roof. In the end, the fan model that’s a little more expensive may offer a better overall $$/CFM cost.

Supplying fresh air to the building can provide cost-effective options based on aesthetics, rain protection, temperature, and free area. Options such as an operable louver, or a louver with a combination damper allow for vent closure to keep rain and cold air out. Louvers with a large free area allow for the efficient flow of fresh air. Either option when paired with a relief fan that’s properly sized, will provide the lowest overall $$/CFM ventilation option for a warehouse, distribution center or manufacturing space.

So, consider all factors, first cost, installation cost, maintenance, and operating cost. Then make the best selection for your needs.

You can find more information on warehouse ventilation in a previous blog post. Read, “Considerations for Warehouse Summer Ventilation Systems.” Learn more about gravity ventilation and powered fan products.

from