The Difference Between Energy Codes and Energy Regulations in the HVAC Industry

Energy codes and regulations have a significant impact on the HVAC industry, however, confusion exists between the two, not only about where they apply but who they apply to and how they are enforced.

Energy codes are generally a set of minimum requirements regarding energy efficiency that must be met in the design and construction of a new building or renovation. They often adopt or refer to standards set by organizations such as the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) with ASHRAE Standard 90.1 and the International Code Council (ICC) through the International Energy Conservation Code (IECC).

Energy regulations are government policies that influence energy use in various applications such as buildings. Government-implemented programs, such as appliance standards that fans and other HVAC equipment adhere to, mandate energy use or efficiency levels. These regulations are generally set to achieve an overall energy savings and emissions reduction target for the nation.

HVAC energy codes and regulations have an impact on the entire building process. Energy codes have more of a direct impact on architects and engineers. The codes are enforced by the building plan inspectors, who hold the engineer accountable, who in turn have to hold contractors accountable for sourcing compliant equipment. Building owners and facilities managers may get involved if they are curious about how it affects the construction budget or operating costs long term.

HVAC manufacturers like Greenheck must ensure products are certified to meet energy performance regulations. Certification is usually supported through trade associations like the Air-Conditioning Heating and Refrigeration Institute (AHRI), the Air Movement and Control Association International, Inc. (AMCA), or the Home Ventilating Institute (HVI). In some cases, manufacturers may be able to self-certify product performance. HVAC products may also need to be listed in state or federal databases indicating their compliance.

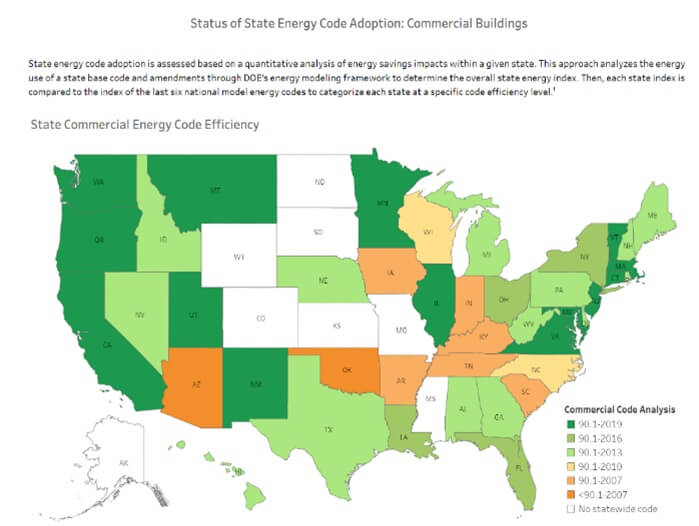

State and local governments are responsible for adopting, updating, and enforcing building energy codes. However, variances exist across states for updating their codes to the latest ASHRAE 90.1 energy standard, a benchmark for commercial building energy codes in the United States. ASHRAE Standard 90.1 provides the minimum requirements for the energy-efficient design of most sites and buildings, except low-rise residential buildings. States were supposed to have adopted ASHRAE 90.1-2019 or an equivalent standard by July of 2023. Currently, not all states have met this requirement as you can see in the graphic below from the US Department of Energy (DOE). States that do not comply may face limits on some federal funding programs but rarely incur a penalty.

|

Status of State Energy Code Adoption: Commercial Buildings Source: US DOE BECP Updated as of 3/31/24 |

Enforcement of energy codes varies a great deal. If a building code is in place and an engineer or contractor fails to follow the requirements, it could result in a denied building permit or a conditional design acceptance. There also could be fines or other legal actions. For most states, it’s something the design engineer handles on their own, and the local plan reviewer may verify that a small list of crucial energy code items is met. Some progressive states require designers to complete and submit a software checklist to verify energy code compliance.

Energy regulations, as mentioned before, are government rulemakings. They are generally not just recommendations, but requirements solidified by law. The one important difference is that complying with regulations is the responsibility of the manufacturer or importer of a product as opposed to a system designer. Failing to meet the requirements for a specific rulemaking can result in fines that are usually on a per-unit basis and may require the removal of the product from the market. Generally, the penalties attempt to make compliance with regulations more cost-effective than paying fines.

Energy codes and energy regulations exist to reduce energy consumption, lower heating/cooling and electrical costs for the end user and protect our natural resources by reducing emissions. An analysis by Pacific Northwest National Laboratory estimated an annual savings of $167 million per year by adopting the 2016 version of ASHRAE 90.1. This is a 3.8% improvement over the 2013 version and a reduction of over 8 million metric tons of greenhouse gas emissions per year. The 2019 version of ASHRAE 90.1 has updated requirements for lighting, window insulation, and HVAC equipment. The code allows for credits and trade-offs which give builders more flexibility to achieve targets. The 2019 version is estimated to drive an additional 10.7% energy savings over the 2016 version, and that’s also another 12 million metric tons of greenhouse gas emissions removed. The 2022 version of ASHRAE 90.1 saves close to 10% more energy per DOE determinations. In addition, a study by Pacific Northwest National Laboratory in New York found that by converting from the ASHRAE 90.1-2016 to the 2019 version saves over $1300 per square foot in construction costs.

Summary

To sum up the differences between energy codes and energy regulations:

- An energy code is a standard that has been enacted into law by a local, regional, or national authority having jurisdiction so that the engineer or contractor is legally obligated to comply with the code. A code might be based on an industry, government, or voluntary consensus-based standard.

- An energy regulation consists of technical definitions, procedures, and/or guidelines that specify minimum requirements or instructions for manufacturers, installers, and users of equipment. Energy regulations generally have certification requirements and can include penalties for noncompliance.

Energy codes and regulations are really about sustainability and stewardship of our natural resources to benefit everyone and our planet.

from